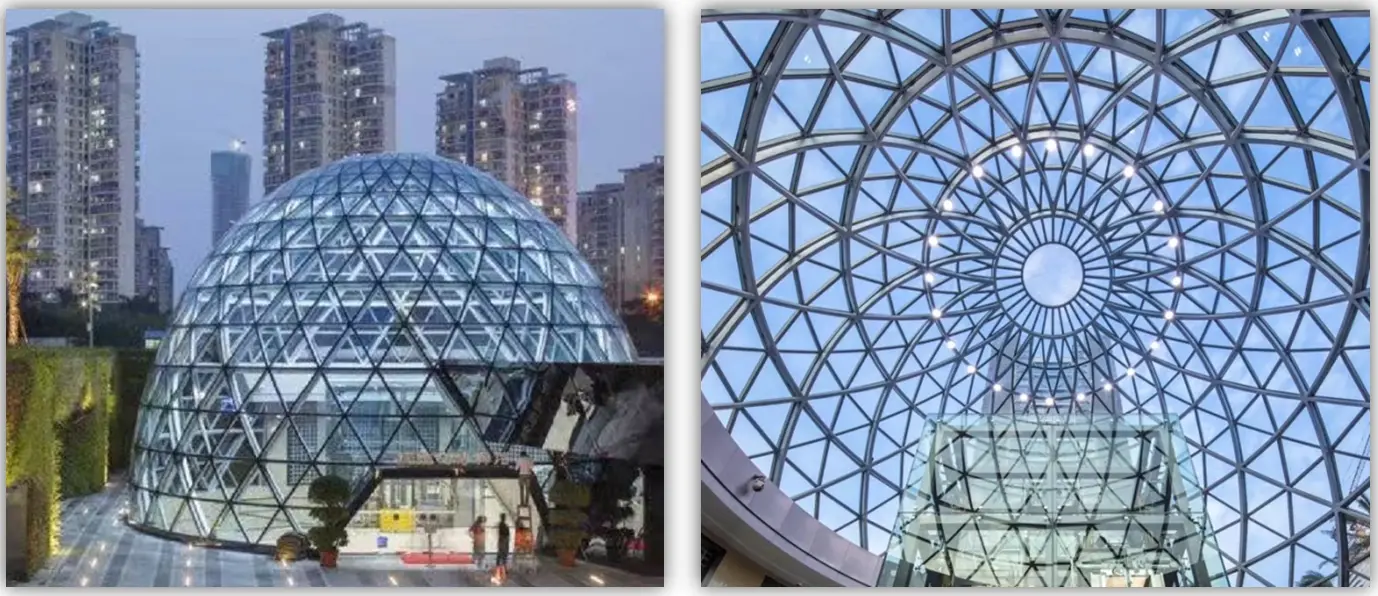

The Ingenious Design of Double-Curved Glass Skylight Roof

This project features a hyperbolic form daylighting roof system. Despite the sphere’s modest radius of only 10 meters, achieving this effect presents significant challenges, requiring solutions to the following issues:

1.Measurement and treatment of deformation in the entire spherical steel structure.

2.Energy efficiency and waterproofing performance of the full spherical daylighting roof.

The simplified design steps are as follows:

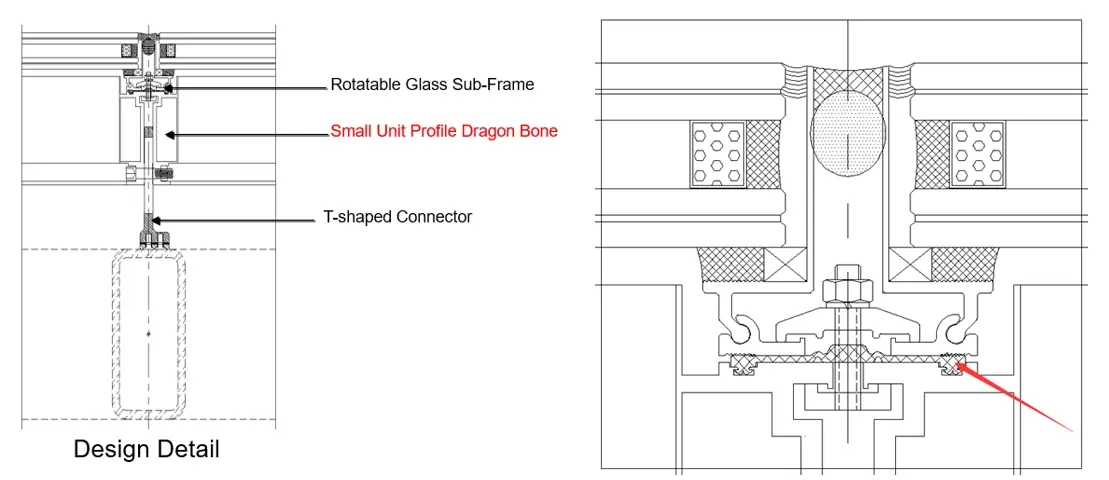

1)Fabricate the mullions for the structural glazing into small units. Three-dimensional adjustability of these units is achieved via T-shaped adapters to accommodate structural steel tolerances. Glass panels are directly installed into their corresponding units, effectively bypassing three common sources of error in conventional framed curtain walls on spherical surfaces: on-site spherical setting-out deviations, mullion installation deviations, and glass panel installation deviations. This approach ensures perfect enclosure of the sphere.

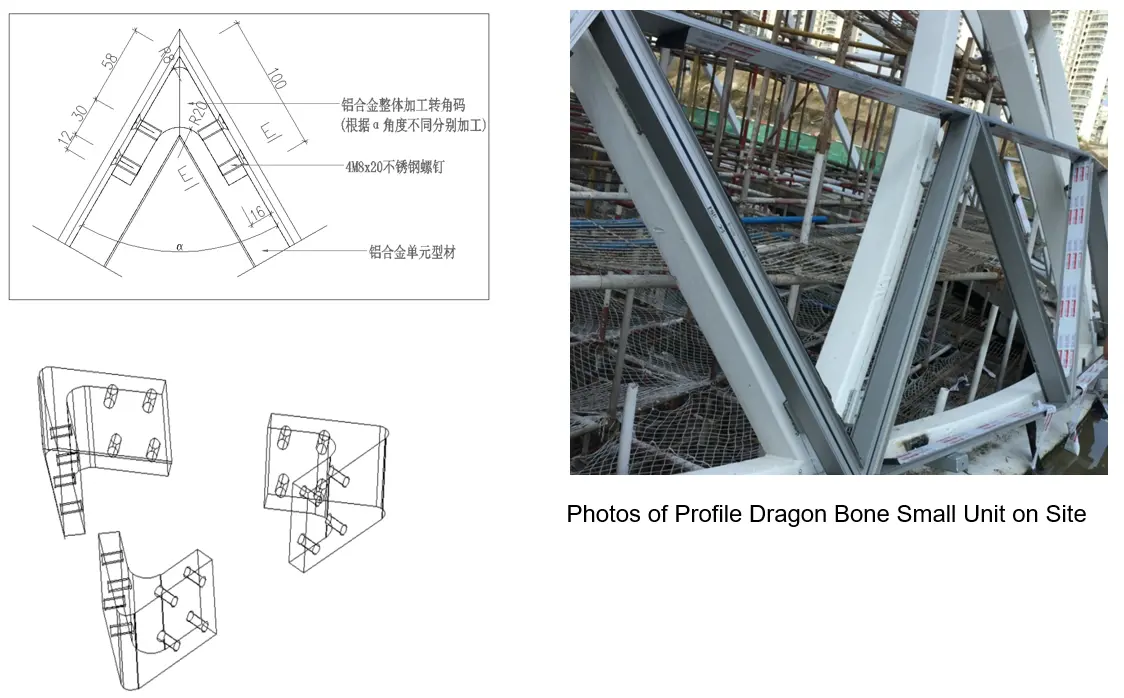

2)Ensure flush corner joints of the mullions by adding aluminum alloy corner brackets at connection points. Based on actual conditions, these brackets require 3D lofting and laser cutting.

3).Specify the following glass panel configuration: 6mm Heat-Strengthened + 1.52mm PVB + 6mm Tempered Double Silver Low-E + 12Ar Insulated Argon-Filled Cavity + 6mm Tempered Crystal Grey + 1.52mm PVB + 6mm Tempered Laminated.

4).Implement a multi-stage waterproofing design, including the addition of a secondary waterproof rubber gasket between the sub-frame and the mullions.